PROCESS ENGINEERING

- Ensuring technical integrity of process engineering deliverables to provide for a safe, efficient and operable facility.

- Designing, optimizing and improving the operation of equipment and facilities

- Advising on process safety issues

- Analyzing and interpreting laboratory and plant data or commission new installations

- Directing and guiding the process engineering activities of the team to generate alternative technical solutions and options during all phases of the project to support business strategy

- Customizing and implementing appropriate process engineering related work procedures and systems

- Identifying and securing the appropriate process engineering resources for the project to deliver quality process engineering deliverables within the agreed project schedule

- HAZOP, HAZID, SIL,

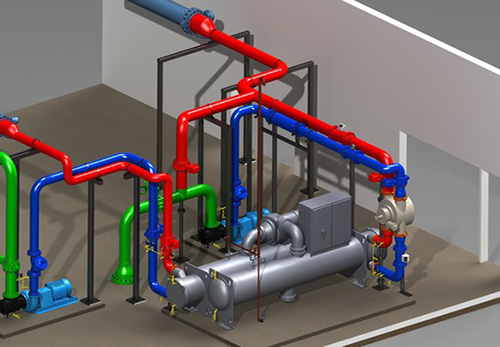

PIPING ENGINEERING

- Project specific standards development

- PDMS development

- Equipment layout engineering

- Piping routing (2D & 3D)

- Piping material engineering & procurement assistance

- (MTO calculation for estimation & procurement)

- Piping support design engineering

- Piping stress analysis engineering

- Reverse engineering (as-built updating)

MECHANICAL /EQUIPMENT ENGINEERING

- Equipment design engineering

- ASME design calculation

- Fabrication drawing

- Tank design and stress analysis

ELECTRICAL ENGINEERING

- Cable sizing

- Cable tray layouts

- Load calculation

- Single line diagram (SLD)

- Generation & updating of single line diagram (SLD)

- Preparation of layout (earthling/lighting)

- Power and control cable design & layout

- SCADA & I/O List

- Interface activities with civil / machinery / instrumentation

- Coordination with civil for floor openings

- Electrical equipment foundation and plants

- Electrical data input for packaged equipment

- Lighting distribution

- Earthing and lightning protection

- Power generation & distribution systems

HSE ENGINEERING

- HAZOP, HAZID, SIL, ENVID, RAM.

- F&G Studies, Dispersion Studies.

CIVIL ENGINEERING

- Design of superstructures for refinery and petrochemical units

- Infrastructure design (water supply, sewage, firefighting networks, trenches)

- Foundation design

- Design and engineering of skids and modular structures

- Pipe and cable rack structures

- Design of foundations for large process equipment

INSTRUMENTATION ENGINEERING

- PLC/DCS (System Engineering)

- Instruments’ datasheets & indices

- Cause & effect diagrams

- Defining field instruments & control panel specification

- Loop drawings

- Instrument & electrical interconnection drawing

- JB & cable schedule

- Logic interlocks drawing

- Instruments cable tray layout

- Instrument location plan

- Bill of Materials

- Level Sketch Diagram

- Instrument & Control Systems

- Tele-communications & data networks

- Fire detection, alarm & protection systems